The La Conner Guitar Festival has come up in the Bench Press before, and with the festival coming up–mighty soon, in fact–we keep finding ourselves returning to the list of luthiers who’ll be there, making a mental list of too many things we can’t wait to check out. Needless to say, the funky creations of Chris and Jeremy Jenkins of Lame Horse Instruments are high on that list. So, after poking around on their website for a little longer than we should’ve it seemed like the responsible thing to do would be to call our dawdling “research” and reach out to Chris to find out a little more about what they’re doing before we meet them in La Conner…

Fretboard Journal: What’s on your bench right now?

Chris Jenkins: The most interesting thing on my bench right now is a Gitjo. We are making a six string banjo for the great John Sebastian. It is a fun project. I have greatly enjoyed working with someone whose music I enjoy so much. I have always been a Lovin’ Spoonful/John Sebastian fan.

FJ: Those Gitjos are interesting… do you make all the hardware? Can you tell us about the pots?

CJ: The Gitjo was Jeremy’s idea. He saw Neil Young play a six-string banjo, and was very taken with it, so we came up with our own design. It is played by a very diverse group of artists, from Don Edwards, the king of the cowboy singers, to Isaac Brock of Modest Mouse. The pot is made up of 84 solid wood blocks glued up, then turned on a lathe. The solid rim gives a much fuller, more woody sound than laminated rims, which pretty much serve to dampen the sound. We do not make the hardware. However, it is all USA-made hardware of nickel plated solid brass. We do make the [wood] Gitjo tailpiece and bridge.

FJ: How did you get started?

CJ: Jeremy, my youngest son and co-builder, and I bought a book and built a solidbody bass about 27 years ago. I caught the bug, and progressed from there. In 2003, Jeremy and I started working together again and have been ever since. The first acoustics happened in about 1997 after attending Charles Fox’s American School of Lutherie. I exhibited at my first Healdsburg festival in 1999, and things just moved on from there.

FJ: Where do you find inspiration?

CJ: Inspiration is all around. It often happens when I hear great players and/or great instruments. Whenever I attend a hand-built guitar festival or exhibition, I am astounded and inspired by the quality of the work being done. It inspires me to try to be better. I am always on he lookout for design ideas – in art, architecture, nature, everywhere.

FJ: Do you have a favorite guitar that’s crossed your bench?

CJ: Lately that is whatever guitar I am currently working on. I hope that continues. We strive to build every guitar as if it will be our last, and try to make it something special. Hopefully we won’t be building anything we are not happy with or excited about. I am too old for that. Who knows how many I have left? I hope all are special.

FJ: Can you tell us about the shop arrangement? Speaking of which, can you tell us some more about the familial collaboration?

CJ: Jeremy and I have separate workshops. His is in Austin, and mine is in Mansfield, Texas. However, every instrument is a collaboration. We ship things back and forth. It is fast and relatively inexpensive via FedEx from Austin to the Dallas-Ft. Worth area. We do work together some, as I travel to Austin, or he comes here. I wish we could work in the same shop more, but it is not possible at this time.

FJ: Do you have a particular philosophy about wood/materials?

CJ: I like any wood that will make a great guitar, and that takes in a lot of wood. Over the years, we have found that Engelmann spruce makes the best tops for the style of instruments that we are building. Almost all the spruces, western red cedar, and redwood make excellent guitar tops, but for the size of our instruments, and the sound we are going for, Engelmann seems to be the best for us. That would not be the case for someone building dreadnought guitars for bluegrass players. The back and sides can help a guitar look beautiful, but they not nearly so important to the sound as the top. As for back and sides, as you might guess, I love woods that are beautiful. We use several different types of ebony, koa, mahogany, Oregon myrtle, bubinga, cocobolo, Southeast Asian rosewood, Madagarcar rosewood, zirocote and others.

FJ: Are there any upcoming projects that you’re particularly excited about?

CJ: I have watched, with interest, The Leonardo Project. It is a group of European luthiers who have built guitars with backs and sides from non-traditional guitar woods. They held blind listening tests to see how these guitars compared to guitars built with rosewood backs and sides. In the blind listening tests, results were exactly 50-50. Half of the people listening preferred the guitars with non-traditional backs and sides, and 50% preferred the rosewood guitars. When the listeners could see the guitars, they overwhelmingly preferred the rosewood guitars. The project confirmed how little backs and sides had to do with the sound of the guitar. It also confirmed how much historical bias there is for rosewood.

In 2016 we exhibited at the Holy Grail Guitar Show in Berlin. They sponsored a Local Wood Challenge for luthiers. Luthiers built guitars from the native woods of their homeland and exhibited them. We were not able to build one for that show due to time constraints. However, Jeremy and I are going to build a Saddle Pal of all Texas woods – beautiful box elder back and sides with an Engelmann spruce top. We are going to build it no matter what, but we hope to get invited back to Berlin in 2018 to be part of the Local Woods Challenge there. I am really looking forward to that.

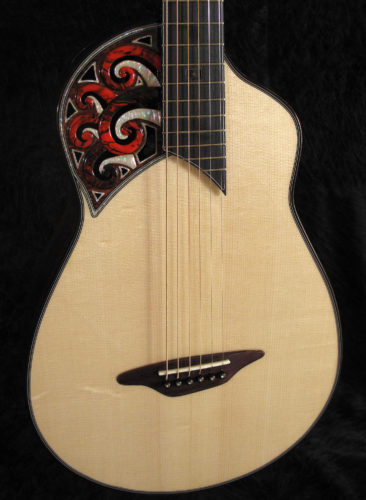

FJ: Speaking of the Saddle Pals, what’s their story? They get some lovely detail work on their rosettes…

CJ: The Saddle Pal is our most original and best-selling guitar. A friend, Andy Wilkinson, who is a Texas songwriter, poet, playwright and journalist, wanted a small guitar that would be comfortable to play and easy to transport. He asked us to build him a guitar that was “small enough to pack on ones saddle, with a sound as big as Texas.” That is what we feel we have accomplished. Because it is small, with a 13” lower bout, the guitar benefits sonically from having a lot of soundholes, and from the soundholes being pushed up into the top and sides of the upper bout. Both of those things help boost the low end. When the soundholes are non-traditional, the design just lends itself to a lot of design work in what we call the rosette. I don’t know if it really is a rosette, but we call it that to distinguish that area and those holes from the ports in the sides of the upper bout of the guitar. With that design, we almost always need sound ports in the sides of the upper bout because we just can’t get enough sound hole area from the rosette. I really love building these guitars.