A random question about working with different types of wood at the mile high altitude in Denver has clearly sparked luthier Greg German’s interest. He reaches behind him and pulls out a piece of rare Brazilian rosewood that he plans to use as the back for one of his Belladonna flattop model guitars.

“There’s something about Brazilian rosewood,” he says animatedly, as he holds it up next to my ears and starts tapping on it. “Listen to it. It’s got a rich tone to it already. It’s like a musical instrument in its natural state. It’s got such a deep, rich sound. Listen to the sustain it has.”

He reaches behind him and pulls out another piece of wood, ziricote, tapping on it and having me listen in comparison; the wood seems a little tinnier. “See, this is nice, but it doesn’t have the depth of the Brazilian rosewood. All Brazilian rosewood that you can still get comes from the stumps of trees that were harvested back in the ’50s and ’60s for furniture and flooring. It’s on the endangered list now, and other woods are being used as substitutes, like East Indian rosewood, but they don’t have quite the same tone as the Brazilian.”

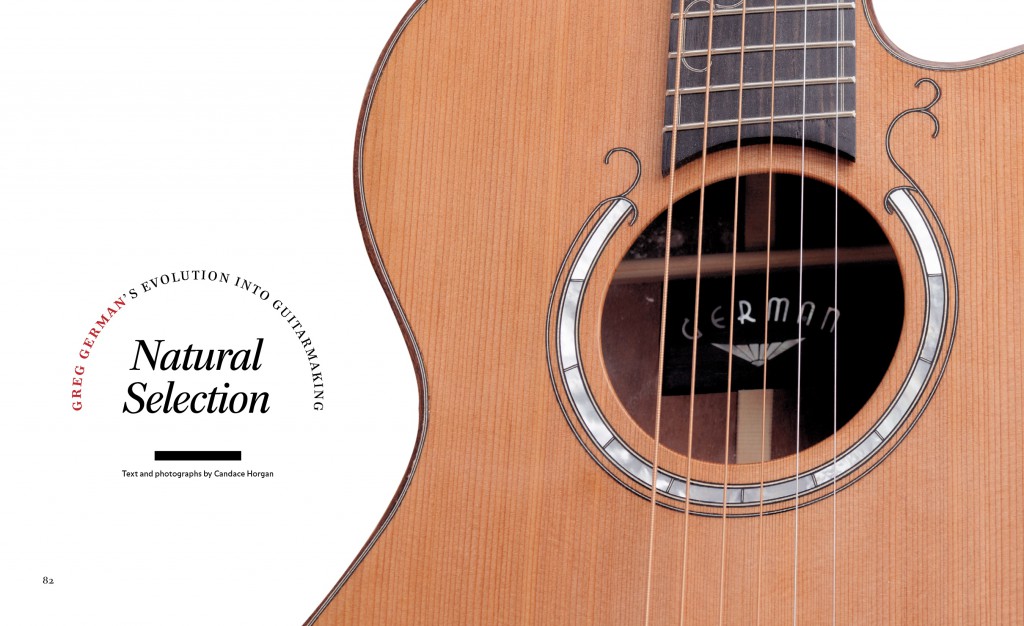

Even in a discussion about the basic parts of a guitar, German’s love of aesthetics and art comes through. Small wonder for someone who has made art in one form or another a driving force of his life. Born in Shreveport, Louisiana, German has taken many different turns in his life before arriving at his current profession as a luthier in Broomfield, Colorado, just outside of Denver, where he not only builds premium archtop and flattop guitars, he operates a rock climbing guide service in nearby Eldorado Canyon State Park. German also serves on the Action Committee for Eldorado, which helps to preserve Eldorado Canyon and also has a branch called the Fixed Hardware Review Committee, which polls climbers when a proposal comes along to either place new fixed hardware or replace existing fixed hardware (typically bolts that are drilled into the rock, providing secure protection, but which look ugly on the rock and are not as aesthetic as climbing with removable protection).

Climbing seems like a foreign recreational activity for someone who grew up in Louisiana, but even guitar building isn’t necessarily something that would have been a natural interest for German, whose own experiences with playing music were fleeting. In fact, his father owned a farm, and German worked on it.

“My dad has Black Angus beef cattle, so from the time I was a little kid through college I would go up to the farm and work cattle,” he explains. “There’s a lot of that kind of work on the farm, building fences and working with a lot of tools and tractors and things. My woodworking experience was more farm-related.

“I have an older brother, Jeff, who has always been more into music than I was, and I wanted to be him. When I was in high school, I started playing guitar because he did. He was in a band, and I ended up being the soundman and roadie for his band. I kind of played around, but never intended to be a performing musician. I was always just kind of playing around with guitar. My brother still plays. He is the music director of sorts for a church in Shreveport.”

After high school, German attended Baylor University in Waco, Texas. (His brother also went there.) German started college as a pre-med major, thinking he would be a doctor like his father. (His brother also became a doctor.) However, he also took art classes at Baylor, thinking he would have a pre-med major and art minor. After a year, he ended up switching those. His science background became important, however, as he pursued a career as a medical illustrator.

“At my 10-year high school reunion, I had several people tell me that I told them in high school that I was going to be a medical illustrator, and I didn’t remember that. I apparently did, because they aren’t lying about it, so maybe I was thinking about it before I thought I was thinking about it! I went to Iowa for grad school. I got an internship at a company called Engineering Animation (EAI) doing 3-D medical illustration stuff, mostly animation. My master’s thesis, instead of being a written paper, was a 10-minute animation on the physiology of hearing and how the hair cells of the cochlea perform a muscular function in fine-tuning tonal discrimination. I still have a copy of it. I graduated with a master’s of art in biomedical communication.”

After earning his master’s, German started working for EAI. The company quickly expanded during the dot-com bubble, eventually employing more medical illustrators than anywhere in the country, with offices in Salt Lake City, Los Angeles and Chicago. At one point, EAI had more than 400 employees in Ames, Iowa, alone. German initially worked on illustrations for textbooks, as well as CD-ROMs and medical drug advertisements. He still has some friends there, but many people moved on after the dot-com bubble burst.

“We all got laid off,” laughs German. “It was kind of a classic bubble where the stock price opened at 16, went to 70-something, and went down to eight. It still exists. It was bought by Unigraphics, and I still have some friends working there in Ames doing the same stuff. It’s not the same as it was. My wife worked there as the librarian, and I worked there as a medical animator. We both got laid off, and I came to Denver to teach at the Art Institute of Colorado, because I had always enjoyed the teaching part of being an animator in Iowa. I would help train other animators in 3-D modeling, which is what I thought I wanted to do.”

However, the job at the Art Institute didn’t last long, as he quit after three semesters, finding that he didn’t enjoy the work. Before leaving for Denver, German had built a Telecaster, and also a copy of a Fender Bassman. He also acquired the Robert Benedetto book on building archtops [Making an Archtop Guitar], which sparked his curiosity.

“My mentor and manager back in Ames, Tim Zwicka, got me building amps,” explains German. “He’s a bass player in a rockabilly band in Austin now. He’s still an animator and a game producer. He was into old tube amps. He built a Vox AC30, and we talked guitars. I had gone on a business trip to the game expo out in New York City, and while I was there, I went to 48th Street. I went into Manny’s and bought a Rickenbacker there. Tim was all jazzed about that. He said, ’You have to build an amp for that. You have to build an AC30.’ I told him, ’Well, no, I like Stevie Ray Vaughan,’ so he told me to build a Bassman, and I did. Mine is built as a combo; I didn’t want four speakers because it would be too heavy to lug around.

“I built a couple of amps, and that got me wanting to build a Telecaster for it. Around this time, I was getting really sick of working at the Art Institute. I said to myself, ’I wonder if there are any guitar builders in Denver.’ I started looking around, and I decided to quit my job and build guitars. Edward Dick at Olde Town Pickin’ Parlor said he took apprentices, and I said, ’OK, I am going to quit my job and be your apprentice, thanks to a very loving and supportive wife.’ She gets major credit for letting me do that.”

Though Scott Baxendale was in Denver at the time and fairly well known, German didn’t approach him, but he did run into Baxendale through the Colorado Luthiers group. What German finds most amusing about his decision to pursue lutherie is its parallel to his decision to go to grad school.

“I just talked to a few luthiers; I didn’t do an exhaustive search,” German says ruefully. “It’s kind of like when I went to grad school; my wife laughs at me when she tells the story. I decided I was going to go to grad school after undergrad, and there’re five schools in the country, and each takes about five students. You’d think I’d apply to them all, right? Nope, I applied to one, and I got in. That’s just how I operated. It’s kind of stupid. I applied to one, and I knew I was going to get in.”

At the Pickin’ Parlor, German did a lot of repairs, working on Taylors, Martins, Goodalls, Collings and others. Dick didn’t take apprentices for building, although he did mentor German as he built his first few archtops. German used the Benedetto book as a model as he experimented with different design ideas. In fact, German still has the first archtop he built hanging on the wall in his shop. (“That was experimental. There are a few things about it that aren’t that great. Cheap wood, and my craftsmanship was meh.”)

He and Dick also built flattops together for a few years under the moniker Victor Guitars (Dick’s middle name). In addition to repairing, he also worked on some other instruments, including zithers (“I learned to hate zithers,” he says. “I have a policy now that I won’t work on zithers!”), mandolins, violins, cellos and double basses. German looks back fondly on his repair tenure with the Pickin’ Parlor, which he feels was very helpful to him as he started his career as a builder.

“The Pickin’ Parlor was a good place to learn, because we’d see $10,000 instruments and when they would stay in the shop for a day or two, you would measure them and see what makes them work [laughs]. You find out what makes a good instrument. Play something that sounds amazing, even if it’s cheap, like some old Washburns, you look inside at the bracing, and you go, ’Oh wow, they did something different here,’ and then you start flexing it and measuring how much the top can flex and you find out some of the things people do right.

“It teaches you how to critique an instrument and what to look for. Repair work also teaches you a few things that builders who don’t do repair don’t learn about: annoying things about instruments that you can build into instruments without knowing it. If you don’t do a lot of neck resets and tons of setups and see twisted necks and things, you don’t realize that your design might be driving repairmen crazy! There are a lot of builders who don’t do repair work, and they can build a beautiful instrument that sounds great but is a pain in the ass to work on. It’s nice to build a beautiful instrument that sounds great and is also easy to repair. That’s something I learned working at the Pickin’ Parlor. At least, I got opinionated about design by working on a lot of different kinds of instruments.”

German started a website in 2001, and the word got out about his instruments, especially his archtops, which remain his first love. In 2006, he and his wife bought a house in Broomfield, and the basement was big enough that he decided he could operate his own shop out of his home.

“The archtop is what drew me to guitar building in the beginning,” he says reverently. “I had built the Tele, but I wanted to make archtops. Benedetto’s book inspired me, and then I did a lot of research into guitarmaking and I thought archtops were just the bee’s knees, and knew I wanted to make them. I still love them. The thing that determines the sound is more the geometry of the curve. It’s graceful. It’s carving the sound into the instrument. It’s more elegant, because you are relying on a singular chunk of wood, and the way you carve that arch, it will be either brittle and strong and glassy, or it will be responsive and dark and boomy, and it all relies on how you carve it, not the bracing. I like the simplicity of the design and the grace of it; there’s just something special about an archtop guitar.”

One of German’s standard archtop guitar models is the DB, which is available in both six- and seven-string versions. The model name comes from the initials for David Bailey, a Denver jazz guitarist who commissioned an archtop from German fairly early in his lutherie career.

“It’s an acoustic archtop with a floating pickup, so it’s not routed,” he explains. “An archtop that is just intended for electric play, like that little Epiphone over there, you route pickups into the top and that kind of makes the top really massive and kills a lot of the acoustic tone of it. The floating pickup on the DB makes it more of an acoustic instrument. Dave said he wanted to do the Charlie Hunter thing, and he wanted me to make a fan-fret, seven-string archtop. I was like, ’Wow, that sounds pretty wild, Dave.’ He offered to help design it, and that’s why I call the model the DB7. He inspired me to kind of go out on a limb to build that instrument, because it was hard. I had not seen a fan fret, acoustic, archtop instrument, and I still haven’t seen very many of them, and I kind of made the project harder by making the whole body skewed to match the fretboard like I do with all of mine now. That leads to a lot of woodworking issues, because all of your joints are skewed. A lot of fan fret instruments have a body and a neck that are joined at a right angle, and then you put a fan fretboard on and put the nut and the bridge at an angle, and nothing else is at an angle. I took everything about the design and made it line up, so all my landmarks moved. It got really hard to build. They are still really hard to build, but I like the challenge.”

For his part, Bailey had sought out the guitar because he had been experimenting with a lot of different tunings in his playing, and he started using unorthodox string gauges that put more strain on the guitar.

“Greg is a very smart person; he sees the long-range goals of a musician and will help design an instrument that will be suited to that music,” says Bailey. “I tune down to a low G; Greg saw that I was seeking out a lower, bassier sound, so he used his brain to find the perfect soundhole placement and bracing pattern to maximize the bass response. A factory just wouldn’t do this, or even know how, really. They sound so good. Secondly, it is a learning experience to have a guitar built. The first guitar Greg built for me, I went over to his house and picked out the wood. Then every step along the way, he was sending photographs. You really get in tune with the process, and are rewarded when you finally get the instrument in your hands.”

In addition to his standard flattop and archtop models, which he will either build on spec or when someone contacts him and asks for a standard model, German sometimes builds instruments by commission, such as a DB7 model he built for Maggie Jones that had a cello end pin, four or five bevels, a wedge body and no binding so that she could play it in an upright position. The guitar was a fan fret model with a two-inch fan fret difference. German generally doesn’t like to build too many guitars unless they are commissioned.

“It’s depressing to build a lot of instruments without buyers,” he explains. “If they sit around, you just feel sad that they don’t have a home, so I do more repair work while waiting for buyers.”

Many of German’s buyers remember him from his days at the Pickin’ Parlor and seek him out. The Internet has helped him to build his reputation, and he regularly attends guitar shows to further get his name out.

“I went to the Guild of American Luthiers show in 2003 with Edward, even though I had no instruments to display that year. After that, there were a couple of local shows in Colorado that the Colorado Luthiers Group did, including at least one at Swallow Hill, and then there’s Montreal. I started to go to the Montreal Guitar Show in 2004, I think. I went every year from there on. Montreal is the main show I go to because that’s where archtop buyers go, because it’s a jazz show.”

Asked about any challenges with the desert climate of Denver and the altitude, German explains that the humidity does affect the repair work he sees, which includes a lot of split tops in the winter from guitars that come from wetter climates. He has also found over the years that some woods do better than others in Denver.

“Some species of wood do not do as well with wildly swinging humidities,” he states. “If you get a maple that’s flat-sawn, it can really twist and move a lot. Mahogany does pretty well. Some woods will shrink across the grain and along the grain, and some will only shrink across the grain. Rosewood fingerboards tend to do better here than ebony. Ebony will shrink in both ways, and rosewood seems to only shrink a little bit in one direction. You make different choices, but you end up building the guitar you are going to build. Climate is not going to change that; you just have to be careful with them. As far as my own building, I’ve got a humidifier over there that’s going 24 hours a day in the wintertime. In the summertime, it’s actually off and I can keep it around 40 percent here.”

In addition to guitars, German has been using the Internet to push his nascent rock climbing guiding business. German had never climbed before moving to Colorado, but shortly after arriving, he took a course with the Colorado Mountain Club and found that his height and reach were a great asset, and he fell in love with climbing. He was quickly climbing 5.9, a level at which true technical difficulty starts on the climbing scale.

“In 2009, I climbed El Cap for the first time,” he says. “We did the Salathe Wall. We had to aid climb a few parts of the Free Blast part of it, at least four or five pitches.” (Aid climbing requires connecting webbing ladders to pieces of protection placed in the rock and then climbing the ladders.) “We didn’t take a hammer. We didn’t want to use any iron. In 2008, we did Space Shot and Moonlight Buttress in Zion. I like aid climbing more than most of my partners do. A lot of people, for them the gear part of trad climbing is secondary, something you have to do to keep yourself safe. It’s a security blanket sometimes. You know you have good gear, but you don’t think about the good gear unless you are scared. For me, the gear portion of climbing is about half the fun, because I really enjoy the act of estimating things and measuring. Most of what you are doing as a trad leader is estimating. What distance is that, what size is that, do I have something that fits it, what is the strength of it, what’s the difficulty of this move, and what’s my likelihood of success? You have all these estimations in calculating risk and also mechanical properties of things, and I love that. I’m a gear geek. I really enjoy the aid climbing because you are engineering your way up a route. It’s a very different discipline than free climbing, but it’s also fun. It’s a nice, physical puzzle.”

In 2008, German took and passed the American Mountain Guides Association single-pitch guide course, and in 2010, he took the multipitch course, then took the exam the following year. He has been gradually building up his guiding practice, but there is a lot of competition in Colorado, a rock climbing mecca.

In late July 2013, German found himself once again at a medical illustrators conference, this time as a presenter talking about what he is currently doing. He was invited to talk at the conference, held in Salt Lake City, by one of his former coworkers.

“He contacted a bunch of ex medical illustrators and asked what we did now, and if we would be interested in coming to the conference and talking about what we do now,” German remembers. “There are a lot of medical illustrators who go on to do other things. I am presenting on 3-D machining. A lot of medical illustrators do 3-D modeling for medical illustration, but until recently they haven’t gotten to build things out of those models, but now there’s 3-D printing, so there are medical illustrators doing 3-D printing of anatomical models and prosthetics and all kinds of things. So the machining process is similar to the 3-D printing process, and some of the challenges you face in making a three-dimensional real world object from your three-dimensional printing model are similar.”

Though German’s many different twists and turns may seem contradictory at first glance, he finds many similarities in lutherie, rock climbing and a career as a medical illustrator.

“In the same way that medical illustration is a lot of art and a lot of science, it’s a commercial art venture for medical clients,” he explains. “Your clients want accurate anatomical landmarks, and they want no extraneous stuff, but they want it to look nice with a blue background. You get to vent your artistic desires while meeting all these very stringent medical, clinical and scientific guidelines about what the art will get across. With guitar building, there’s a lot of aesthetics involved. You choose the design, you choose what kind of guitar you want to build, and you can make it look like just about anything. Style is very broad. But there are very stringent requirements on the physical object, and how to make it work involves engineering and physics and acoustics and a lot of judgment. Instead of being medical and clinical science, it’s hands-on science, which is a slight difference.

“I know it’s been debunked about the whole left brain-right brain dichotomy; you use your whole brain, and the left brain thing is kind of a wives’ tale now, but you can say that medical illustration is kind of a right and left brain thing, and so is guitar building. There’s a lot of the artistic and vague kind of stuff, and a lot of the hard-edged science stuff that you have to use. I think guitar building attracts the same kinds of personalities to it. The same temperament is involved in guitar building as in medical illustration. I remember in grad school with pen and ink drawings, we would sit and stroke equally weighted, equally spaced lines with a pen, where you dip it in India ink and you are just making a line, and then another line about a half-millimeter away, and you do about a hundred of those and try to get to where you can control that pen. It’s tedium, but the point of it is to be able to make thin and thick lines so you can make that shading of drawings like you see on a dollar bill. So you can control the pen. But the practice was tedious and involved extreme attention to detail. There’s a lot of that in guitar building! There’s a lot of sanding and scraping and carving, but I enjoy it, and it feels like the same thing to me as creating a drawing.”