Larry Robinson is one of the instrument world’s finest inlay artists and his reputation for meticulous craftsmanship and maniacal attention to detail is well earned. So it’s ironic that his inlay career began when he needed to cover up a major blunder. “I started building acoustic guitars in 1972,” he recalls. “In 1975 I got job working for Rick Turner at Alembic Guitars. They built solid-bodies, and, in my youthful ignorance, I figured they were easier to construct than acoustics. That’s probably why I wasn’t paying close attention when I drilled completely through the backs on the two basses I was putting pickups in.”

After surveying the damage, Turner decided that, rather than fire Robinson, he would teach the young luthier the rudiments of inlay so he could artfully cover the holes. “I inlayed a pearl hummingbird in the back of one bass and a flower in the other,” Robinson says. “And now that they were custom instruments, Rick raised the price on both guitars. That mistake taught me quite a few valuable lessons.”

In early 2002, 30 years after he built his first guitar, Robinson got a call at his northern California workshop from Dick Boak, the man in charge of special projects at C.F. Martin & Company. “He said that they were going to build their millionth guitar soon, and C.F. Martin IV, the great-great-great-grandson of the man who founded the company, thought that Martin should do something suitable to celebrate the milestone,” Robinson explains. “I had worked on two other very fancy guitars for the Martin company—the D-45 China Dragon and the D-45 Peacock—and Dick said they were looking for something that would surpass those in terms of ornamentation and would also encapsulate the company’s 171 years of history. I was very honored that they chose me to work on such an important project.”

Over the years Robinson honed his technique on countless intentional inlay jobs, and by the mid-1980s he was the guy you called if you wanted something spectacular inlaid on your instrument. He has worked with just about every important guitar builder in America, including Martin, Gibson, Fender, the Santa Cruz Guitar Company, National Resophonic, Kevin Ryan, James Olson, Lance McCollum, and Kathy Wingert, as well as taking commissions from hundreds of individual customers.

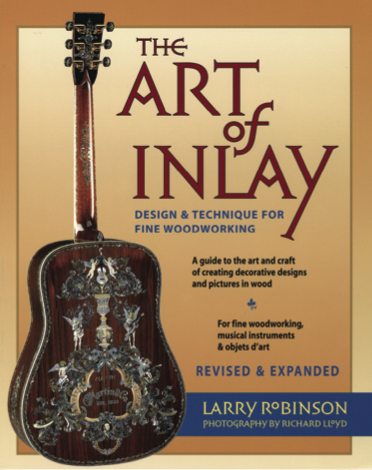

In 1994 he published The Art of Inlay, a book that revealed some of the secrets of his craft. “When I was learning how to do inlay, lots of other artists were very generous with their advice, so I felt like this was a way to pass some of that on to the guys coming up,” he says. “Also, I had been backlogged for so long, I thought that if there were more people out there doing this, it would relieve some of my workload. Sadly, the book just increased my visibility and I had more work than ever.”

Robinson revised the book in 1999 and again in 2005. “Some of my techniques have evolved over the years, so it seemed like a good idea to update the book,” he says. “I’ve also included sections on inlaying 3-D designs, repair, and a bit on how to cut slabs from raw shell.” Although the book is aimed at the working luthier, instrument lovers will love poring over the dozens of color photos of some of Robinson’s finest creations. And in a generous touch, Robinson has included a gallery of work from other inlay artists including Grit Laskin, Renee Karnes, Paul Reed Smith, Ren Ferguson, and Richard Hoover.

But the highlight of the book is the collection of photos tracing the creation of Robinson’s most complicated and ornate job to date: the Millionth Martin. After he began contemplating the guitar and tried a variety of design styles, he opted to use a blend of baroque and Victorian imagery. His first version of the back design featured a large eagle clutching a Stauffer-style guitar in one talon, as well as a number of heraldic elements like crowns, shields, and a coat of arms. “Dick Boak liked the way the design was going,” Robinson says. “But C.F. Martin, or Chris as everyone calls him, said that his family wasn’t royalty so I should tone down the regal imagery. He did like the cherubs, which I had playing violins and violas de gamba, but he thought it would be more appropriate to have them playing Martin instruments, so I changed that as well. In the final version I had them playing a D-28, a ukulele, an A-style mandolin, and a 000-28.”

Robinson replaced the eagle on the back with an urn overflowing with acanthus leaves, a decorative motif commonly used in Victorian design. He felt it was important to retain the eagle (the national symbol of both Germany, where the first C.F. Martin was born in 1796, and the United States, where he founded his guitar company in 1833), so Robinson designed a smaller eagle for the headstock. One small remnant of the regal design did survive though. “I designed a shield with a guitar top showing Martin’s famous cross-bracing pattern,” Robinson says. “I wound up using that on the pickguard.”

Robinson and Martin decided to use an ultra-elaborate tree-of-life pattern in the fretboard and around the soundhole. Robinson also designed an abalone and gold soundhole “rose” that recalled the decorations used on baroque lutes. The design also included nods to the company’s heritage with a representation of the Stauffer-style of guitar that C.F. Martin built in the early days of the company; an engraved bust of C.F. Martin himself; and inlays featuring the hand tools he used to build his guitars.

After getting final approval on the design, Robinson began to assemble the materials. Martin craftsmen would build the guitar, which was essentially a D-45 with Brazilian rosewood sides and back and an Adirondack spruce top, but Robinson would be responsible for all of the decoration. He decided to use a combination of abalone, mother-of-pearl, and sea snail for the larger sections of the design and then use 18k gold, white gold, and silver to highlight various elements. As an added bonus, he incorporated diamonds, rubies, emeralds, sapphires, and aquamarines into the patterns.

Robinson estimated that it would take more than a year to complete the job. “All of my work is done by hand,” Robinson explains. “I use a jeweler’s saw to cut out the pieces, which I think gives the cleanest outlines and the sharpest angles. I find that CNC machines, the computer-controlled cutters that a lot of guys are using now, just don’t have the ability to create sharp angles. Even the smallest cutting head is incapable of making a sharp-angle cut like a jeweler’s saw.”

As proud as he is of his skill, Robinson sometimes wished he were as tireless as a machine. “There were about 2400 pieces in the floral border that went around the back, sides, and neck,” he says. “Not only was it difficult to cut them all out by hand, but keeping track of all of the tiny bits was very complicated as well. After doing the border I decided I didn’t want to count the other pieces and just focused on the section I was working on.”

Robinson usually works alone, but on this project he realized he could us some help with the metalwork and the engraving. For these specialized skills he turned to David Giulietti, a craftsman he had worked with on guitars for National Resophonic and Fender. “Larry had me carve the gold leaves on the bridge tips and the backs of the tuning machines as well as the gold flower in the center of the soundhole cover,” Giulietti says. “I also engraved the faces of the angels and C.F. Martin’s face. I used extremely fine engraving tools, and to get the subtle shading it took five weeks of six-to-eight hour days doing the work by looking through my binocular microscope. Larry and I worked hard to get everything as good as it could be. We both had the attitude that you only get one chance to work on a project like the Millionth Martin, so we had to get it right.”

Robinson’s almost fanatical attention to detail reveals itself the closer you look at the guitar. The hand tools inlaid in the pickguard, for example, feature metal blades and wooden handles just like their three-dimensional counterparts, while the angels finger recognizable chords on their respective instruments. And for the acanthus leaves on the back, Robinson sorted through hundreds of slabs of abalone shell to make sure that the symmetrical inlays on the left and right matched as closely as possible.

The Millionth Martin is certainly a magnificent example of decorative art, but it is first and foremost a tool for making music. Robinson had a chance to play it after it was finally set up and thought it sounded very good. “It probably has four or five pounds of shell and metal inlaid into it, but it hasn’t affected the tone as much as I thought it would,” he says. “I know that Chris Martin has been taking the guitar around the country and displaying it at festivals and workshops. And, to his credit, he’ll let just about anybody play it. I’ve worked on a lot of guitars that are almost never taken out of their cases, but I think it’s really cool that, not only was I able to work on such a historic milestone, but that guitarists will be able to see it and hold it in person.” And with every chord those guitarists play on the Millionth Martin, it’s as if they’ll become part of the guitar’s story as well.