We talk a lot about how we find builders to profile in the Bench Press. Sometimes readers recommend their favorites; sometimes we see them at a show; sometimes they find us. We found Butch Boswell, of Boswell Guitars, all three ways. Several readers have recommended him, he showed up at our door with a couple of guitars, and then we ran into him again at the La Conner Guitar Show–he was definitely on our radar, but somehow slipped through the cracks…

Butch makes cool guitars down in Bend, Oregon. They’re vaguely Martin-flavored, inspired by the classics, but also sporting forward-thinking features. He’s got an impeccable pedigree for a luthier–he studied architecture and cut his teeth in a small shop, at Taylor, and at the legendary Rudy’s Music Stop in New York City. But why am I telling you this? Let’s let Butch answer the questions…

Fretboard Journal: What’s on your bench right now?

Butch Boswell: I have five acoustic instruments I’m working on right now, in various stages of production. A koa/Italian spruce 00-14 is in final cure, waiting for assembly, while a beautiful little koa/sinker cedar tenor uke is just about completed. I hope to be delivering both of these very soon. I’m just getting rolling on two customer orders: an East Indian rosewood/Sitka spruce 00-14 and a Brazilian rosewood/torrefied Adirondack spruce 000-14 (all torrefied bracing as well). Last, and certainly not least, is a very special design Koa/Carpathian 00-14 for the upcoming SBAIC show at the end of August, assuming I can get it done in time. I’m also up to my ears in repair work as of late.

FJ: How did you get started?

BB: I started in the guitar world about 25 years ago in a small shop in San Luis Obispo, California called Blue Note Music. I was going to school for Architectural Engineering, and needed a part-time job. At the time, it was more just a general love affair with actually playing guitar, but over the next several years, instrument repair and construction became my primary focus. I worked at Blue Note for several years before I graduated and moved to San Diego.

Next, I worked at Taylor Guitars for a few years doing both production and warranty repair. I often look back at my time at Taylor as my “Guitar Repair Boot Camp.” I realized pretty quickly, though, that the factory environment wasn’t really my thing. So, to the East Coast I went, where I spent the next few years working at Rudy’s Music Stop in New York. At Rudy’s, vintage guitar sales and restoration were the focus. This was definitely my thing. I handled every kind of vintage, highly collectible instrument, from just about every year, you could imagine. It was an amazing experience, and I’ll never forget the kindness of Rudy, his family and his crew.

Shortly after that I moved back to California and opened my own repair/consignment shop called Butch’s Guitar & Repair. Occasionally, especially being a relatively young repair guy, I would have a hard time convincing customers to let me work on their valuable vintage guitars. So I built my first acoustic to show them that, yes, I truly was a “luthier” and not just a guitar tech. Keep in mind, this wasn’t me framing up the notion of a tech/repair-person being less talented than a builder, but, it was something I ran into often. I strongly believe a good repair person can make a great builder, but not always the other way around. Everything about building hooked me instantly, and it synced perfectly with my background in architecture and engineering–the process, the artistry, the form and function, and more than anything else, the materials. It fascinated me then, and it continues to fascinate me just as much, if not even more so, today.

FJ: Where do you find inspiration?

BB: When I first started out building, I was heavily influenced by the vintage Martin guitars I had grown accustomed to working on. Traditional scalloped, forward shifted X-brace patterns, with appointments based on the 18 and 28 styles. As time has passed I’ve become much more inspired by the new, and the different. As I’ve started attending some guitar shows (La Conner, SBAIC), I’ve realized the need to not just make a killer playing and sounding guitar, but to incorporate some more of the artistic side of things as well. There is such an incredible group of young and hugely talented luthiers out there these days. Every time I look at their work, I can’t help but get inspired. Sometimes depressed, but usually inspired!

FJ: Your acoustic guitars seem like a nice mix of designs in the Martin tradition with modern touches (like soundports). How’d that come about?

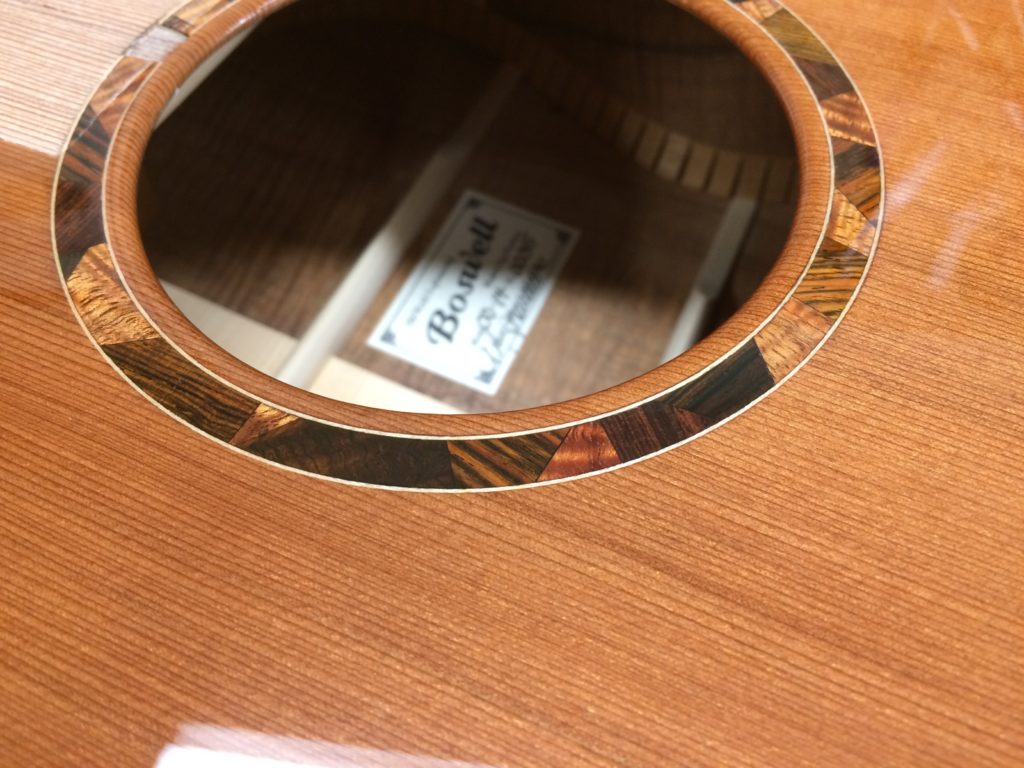

BB: I’d say a combination of tradition and experimentation. Working on all of those old guitars was bound to affect my designs. At the same time though, I want to make sure to put my own stamp on my builds. Trying new things and experimenting is obviously what’s really fun for builders, but you have to keep in mind your branding and style. It’s great when I get a customer that really wants something different and a little more experimental. At times, that may just mean interesting combinations of materials, soundports or edge bevels (my current favorite touch is a tiled ‘mosaic’-style rosette). While at other times, it could mean an adventurous inlay project or new experiments with bracing patterns.

FJ: Do you have a favorite guitar that’s crossed your bench?

BB: Quite honestly, it’s hard to keep track. I’ve been repairing for upwards of 25 years now. Working at Rudy’s in New York was by far the pinnacle of my vintage guitar repair career. Every day, many times a day in fact, something amazing, old, rare and EXPENSIVE would pass through the doors. In one week, the sales side of the shop sold two ’58 ‘Burst Les Pauls! Stuff like that was always going on. A set of three Gibson acoustic instruments has always stuck in my head though. They were referred to as “The Century Set,” and were originally made for the Century of Progress Exposition in Chicago, 1933. The three that Rudy had were all original, in great shape, and consisted of a small archtop with a flat back, an L-00, and a mandolin. Rudy believes this set was from 1935, but many sets were made starting in ’33 up to ’37 or ’38. There was just something so cool about this set of three guitars, surviving as long as they had, and managing to stay together the entire time.

FJ: Can you tell us about your shop? Where’s it located?

BB: I moved my family up to Bend, Oregon about two years ago now, leaving two decades worth of clientele back in California. At first, I wasn’t able to find the right space in Bend, so I setup a shop in Sisters, a small artist community outside of Bend by about 25 miles. I was getting absolutely no traffic out there, and the repair side of the business got a little dicey for a while. I just wasn’t prepared for the idea of truly starting all over again! Fortunately, my wife found a killer little spot in Bend which is where I am now. I love my little shop, and the workload has picked up again to somewhat more normal levels. It’s small, but I have everything I need to both build and repair instruments. I’ve only been in this space for about a year, so I know it’s just going to get better and better.

FJ: Do you have a particular philosophy about wood/materials?

BB: Of course. Older is better. I know I’m not the only one who thinks this and with all of the talk these days about old growth, and the huge spike in torrefied tone woods to emulate “old,” it’s a pretty common way of thinking. I take it to the extreme though, and only use old-growth (and sometimes torrefied) materials for the entire build… every time. The first reason it’s so popular of course is tonality. It sounds better, has a killer ‘ring’ and tap-tone, and a strong fundamental. Wood that still has a lot of water and resins trapped in its cells does not. It sounds wet, and doesn’t ring out when you tap on it. Second, the stability factor is equally important to me. Repairing guitars through the years, the most common repair I did was cracks from the box drying out. So much production grade wood these days is rushed to be used in guitars. It’s kiln dried, and so much of it is still “green.” There is absolutely no way I’m going to build a high-end instrument and then send it out into the world with unpredictable results. With the older tonewoods, they are what they are. They aren’t going to change a whole lot. When a box is assembled with materials that are stable, I’m assured I won’t see that guitar again for repair work. I don’t have a repair department! These older materials can be significantly expensive, but I feel it is absolutely worth it.

FJ: Are there any upcoming projects that you’re particularly excited about?

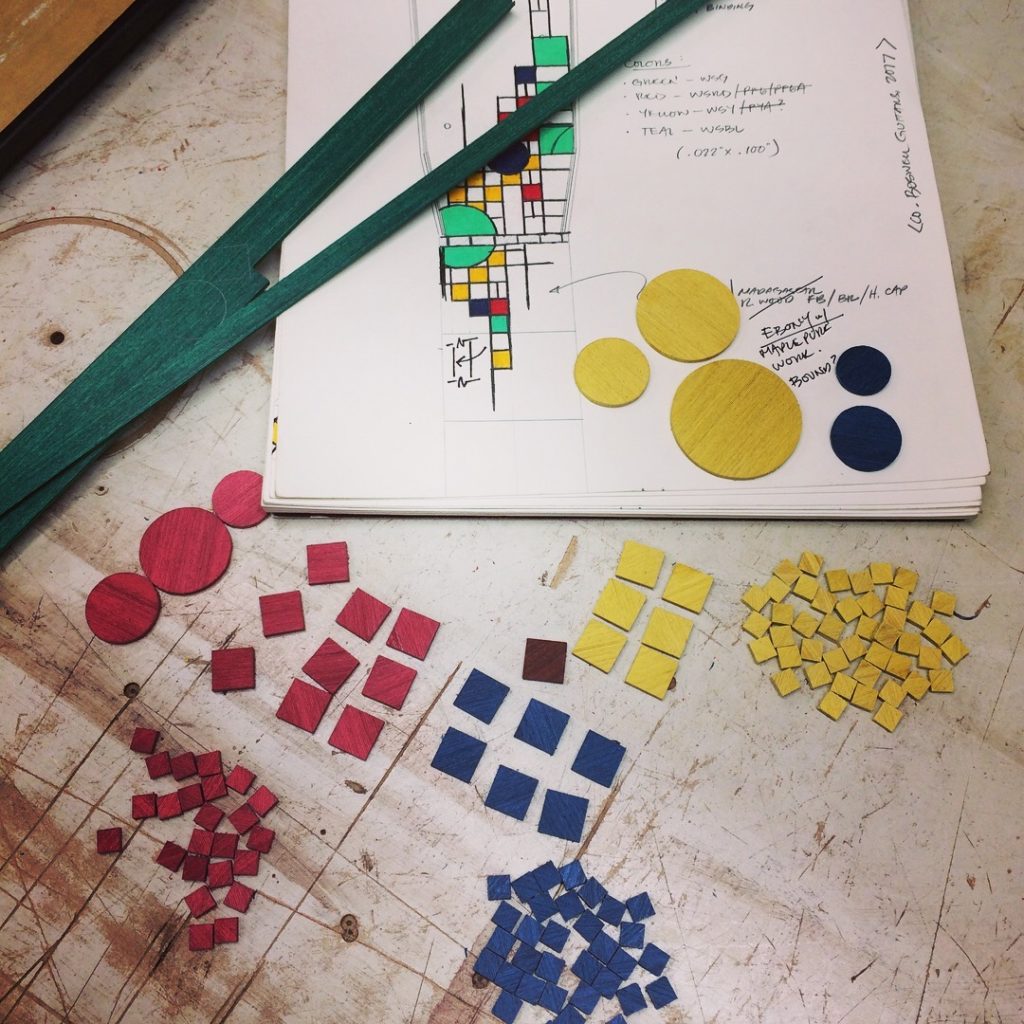

BB: I’m just starting a build for the upcoming SBAIC show, although at this point, I’m feeling like I may not make the deadline! It’s a 00-14 fret guitar, with an incredible set of highly-flamed koa back and sides, and a pristine European spruce top. I’ve been wanting to do a Frank Lloyd Wright, stained glass-inspired guitar for a long time now. I designed the inlay layout several years ago for a friend who was interested in a potential build, but it fell through. So, I’m just now getting back to it. Wright designed his own stained glass accents in nearly all of his windows, and they’re just beautiful. Usually somewhat random patterns of colored glass circles, and squares, with amazingly detailed border and line work. I’m making all of the shapes from colored wood veneer strips glued together, then cut to shape. I’m not big on abalone and pearl, so making a guitar with this much inlay, and using all wood, is right in my wheel house. It’s turning out to be incredibly complex, and it’s easy to see why I stepped away from it for so long, but I love the idea of bringing together my backgrounds in both architecture and guitar design. When all is said and done, it’ll take me three times as long as any other build.